Servo Motor Cables: Applications and Optimization

Release time:

2025-04-18

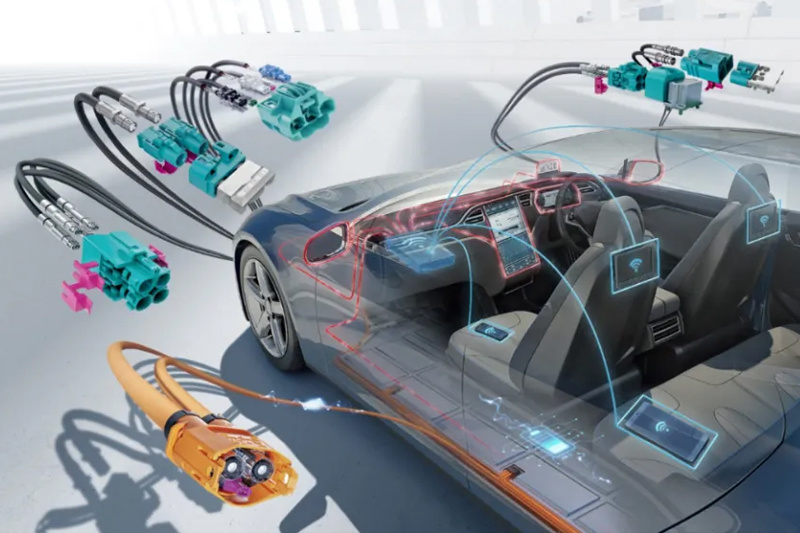

Servo motors play a vital role in modern industry, manufacturing and other technical fields. As the main bridge connecting servo motors and control systems, the application and optimization of servo motor cables are directly related to the performance and stability of the equipment.

Servo motor cable: application and optimization

Servo motors play a vital role in modern industry, manufacturing and other technical fields. As the main bridge connecting servo motors and control systems, the application and optimization of servo motor cables are directly related to the performance and stability of the equipment.

1. Application of servo motor cables

1. Choose the right cable type: According to actual needs, choose cables with good insulation, anti-interference and wear resistance.

2. Cable length and path planning: According to the equipment layout and working environment, reasonably plan the cable length and path to ensure that the cable direction is reasonable, beautiful and easy to maintain.

3. Cable connection: Ensure that the cable is firmly connected to the servo motor and control system to avoid failures caused by poor contact.

2. Optimization of servo motor cables

1. Reduce resistance: Select cable materials with good conductivity to reduce resistance, reduce energy loss and improve transmission efficiency.

2. Enhance anti-interference ability: Use shielded cables, reasonably arrange cable directions, reduce electromagnetic interference and other measures to improve the system's anti-interference ability.

3. Improve wear resistance: Select cable materials with good wear resistance to increase the service life of the cable.

4. Optimize heat dissipation: Rationally design the cable structure to improve the heat dissipation performance of the cable and ensure long-term stable operation.

5. Protection and maintenance: Regularly inspect and maintain the cable to ensure the integrity of the cable and extend its service life.

In actual applications, the following points should also be noted:

1. Avoid excessive bending: Excessive bending may cause damage to the internal wires of the cable and affect performance.

2. Avoid excessive stretching: Ensure that the cable is firmly fixed to avoid excessive stretching during operation.

3. Protect the external environment: Ensure that the cable is away from water, high temperature, and corrosive environment to avoid damage to the cable.

4. Redundant design: Set up redundant cables at key locations to cope with emergencies and ensure the stable operation of the equipment.

In short, the application and optimization of servo motor cables are crucial to ensure the normal operation of the equipment. In actual applications, it is necessary to select the appropriate cable type, reasonably plan the cable layout, and strengthen protective measures according to the specific situation to ensure the stable and efficient operation of the equipment.

Previous page

Next page

Previous page

Next page

Latest From the Blog