The situation of the automotive wiring harness industry chain

Release time:

2025-04-10

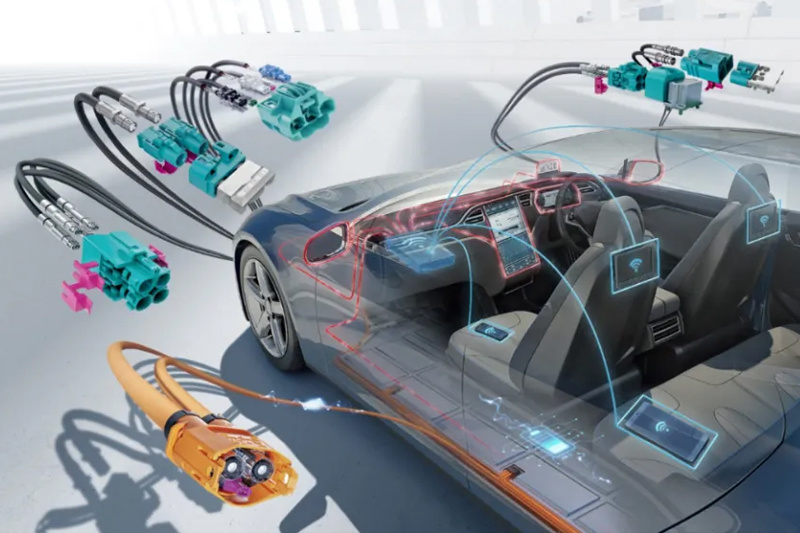

The upstream and downstream industrial chain of the automotive wiring harness industry covers multiple links such as raw material supply.

The upstream and downstream industrial chain of the automotive wiring harness industry covers multiple links such as raw material supply, wiring harness manufacturing, and vehicle matching. Next, we will analyze the industrial chain of the automotive wiring harness industry from three aspects: upstream raw materials, midstream manufacturing, and downstream applications.

1. Upstream raw materials - stable supply

The main raw materials for automotive wiring harnesses include copper, aluminum, plastic, rubber, etc. At present, the supply of these raw materials is relatively stable with minimal price fluctuations. The labor cost accounts for about 12% -17% of the total production cost, while raw materials account for 70-80%. With the gradual recovery of the global economy and the sustained prosperity of the automotive market, upstream raw material suppliers are also constantly expanding their production capacity to meet market demand. At the same time, some raw material suppliers are actively developing new materials to improve the performance of automotive wiring harnesses and reduce costs.

2. Midstream manufacturing process - fierce competition

The manufacturing process of automotive wiring harnesses is the core part of the entire industry chain. At present, there are numerous domestic automobile wire harness manufacturing enterprises, but most of them are small in scale and have uneven technological levels. In order to establish themselves in the market, some companies have begun to increase their R&D investment, improve product quality and performance. Meanwhile, some powerful enterprises have also expanded their production scale and increased market share through mergers and acquisitions. However, with the intensification of market competition, the cost pressure on the manufacturing process is also constantly increasing.

3. Downstream applications - diversified demand

The downstream applications of automotive wiring harnesses mainly include traditional fuel vehicles, new energy vehicles, and various commercial vehicles. With the continuous development of the automotive market, the demand for automotive wiring harnesses in downstream applications has also shown diversified characteristics. The demand for automotive wiring harnesses in traditional fuel vehicles mainly focuses on basic electrical connections and signal transmission; New energy vehicles have put forward higher requirements for high-voltage wiring harnesses, battery management system wiring harnesses, etc; Commercial vehicles place greater emphasis on the reliability and durability of wiring harnesses. These diverse demands provide broad development space for the automotive wiring harness industry.

Next page

Latest From the Blog